How to Use the Hierarchy of Hazard Control in Your Workplace Safety Plan

When building a workplace safety plan, there are many different approaches to take. Although certain aspects of workplace safety are mandated, there are different ways in which safety can be achieved within those mandates. Your organization may opt for one route where another organization chooses another.

On the surface the biggest reason for workplace safety is that it protects and benefits employees. But it also provides protection and benefits organizations. Safe workplaces save money, have more productive employees, have a better community image, and, or course, prevent workplace injury and illness.

Creating a workplace safety plan

No matter the specifics of your workplace safety plan, it is important to make sure it is as easy to follow as possible. Where required, safety education and training must be part of the safety plan and provided to your employees.

Even with the best of intentions, people are unable to follow the rules if they don’t know how or don’t understand them.

When creating and implementing your workplace safety plan it needs to be comprehensive and include multiple fail-safes. A recent global example of fail-safes is the common dual mandate of social distance as well as masking for COVID-19. Both create a barrier for transmission of Covid-19, but together they are more effective and reduce risk of transmission if one should fail.

Overview of the Hierarchy of Hazard Control

The hierarchy of hazard control is a means of determining how to implement control solutions to lessen occupational risks. The hierarchy itself is made up of 5 tiers. The top tier, elimination, is perceived as the most effective in protecting individuals from risks. The following tiers are progressively less effective, with the final tier, Personal Protective Equipment (PPE), as the least effective.

An elimination control is one that removes a risk altogether. With the hazard no longer present, the individual is no longer in danger. An elimination control could be removing flammable materials from a workstation where hot work is being performed to eliminate the risk of fire.

Substitution control involves replacing the safety concern with something that is not hazardous. As the replacement is not dangerous, the risk is mitigated. For example, instead of using a solvent-based paint for a project, a less hazardous water-based paint could be used.

An engineering control is designed to protect individuals from hazardous conditions by preventing contact between them and the risk. Even though the hazard is still present, by preventing contact, this control lowers risk. This can include improving a building’s air filtration systems to remove hazardous materials from the air that employees breathe.

Administrative controls lessen the threat to an individual by changing the individual’s behaviour. This can include policies, procedures, and training. A common example of an administrative control is required training to operate certain equipment or machinery on a construction site.

The final hazard control, PPE, includes anything that is a garment or piece of equipment that protects the wearer’s body from the risk. By creating a physical barrier between the individual and the risk, the risk is lessened. Any kind of safety equipment, such as gloves and masks for medical professionals, fall under the category of PPE.

In the COVID-19 mask and social distance example, this dual mandate also takes advantage of the hierarchy of hazard control, implementing both PPE and administrative controls.

How to prioritize the Hierarchy of Hazard Control

As one would expect, it is important to prioritize the highest tier first in your workplace safety plan, as it is the most effective at providing protection to workers and other individuals. To help create your plan it is recommended to start at the top of the hierarchy and work downwards, using the bottom tiers as fail-safes for the top tiers.

As much as you might prefer to use elimination or substitution controls, sometimes it is not possible given the work environment, requirements of the situation, or scope of the role. Work sometimes has to be done in hazardous situations, or with hazardous materials. In cases where they cannot be used, the bottom tiers can then be utilized to help protect individuals from these present risks.

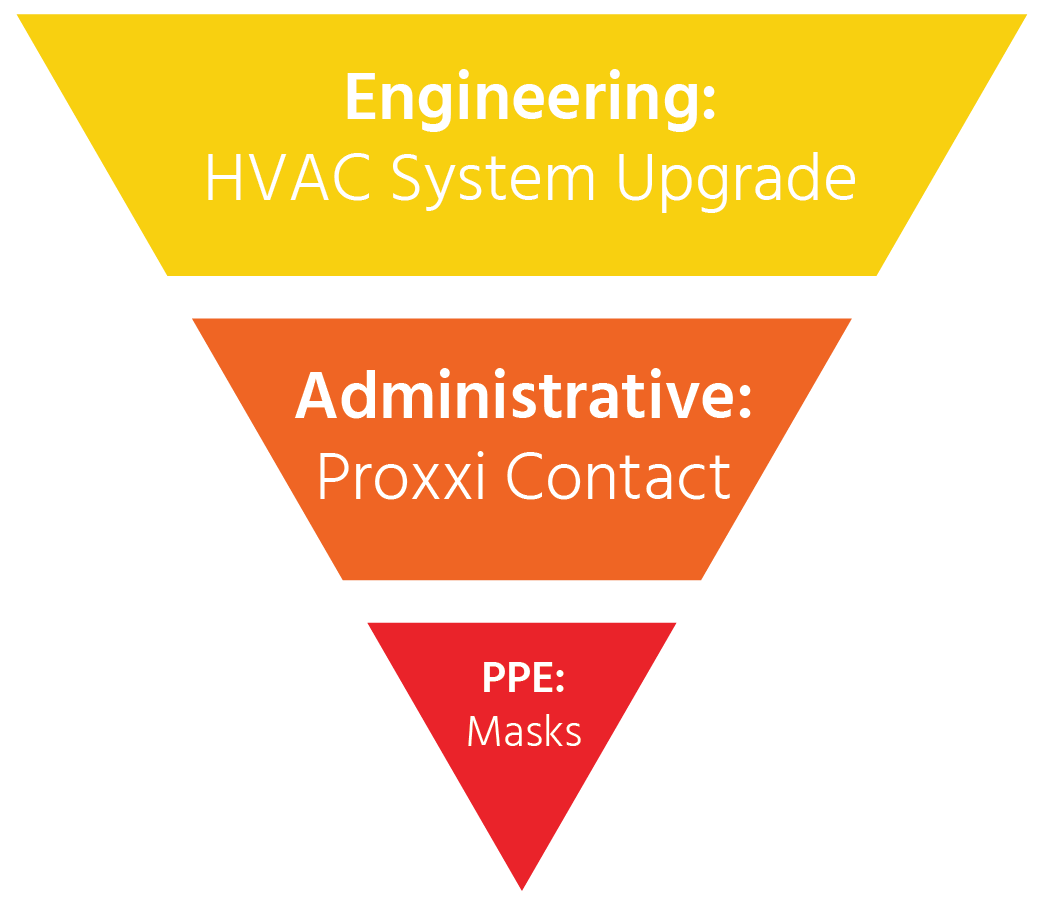

With Covid-19 we saw some companies use elimination controls, such as mandating work-from-home, to eliminate the risk of on-site transmission. For many organizations, elimination and substitution controls were not an option. Administrative controls, such as mandated health checks, masks, or other PPE became standard. For organizations looking to make their workplace safety plan more robust, Proxxi Contact provides an additional administrative control, by warning employees of contact when they come close to one another. It also improves contact tracing by increasing its speed and accuracy, adding to existing administrative controls.

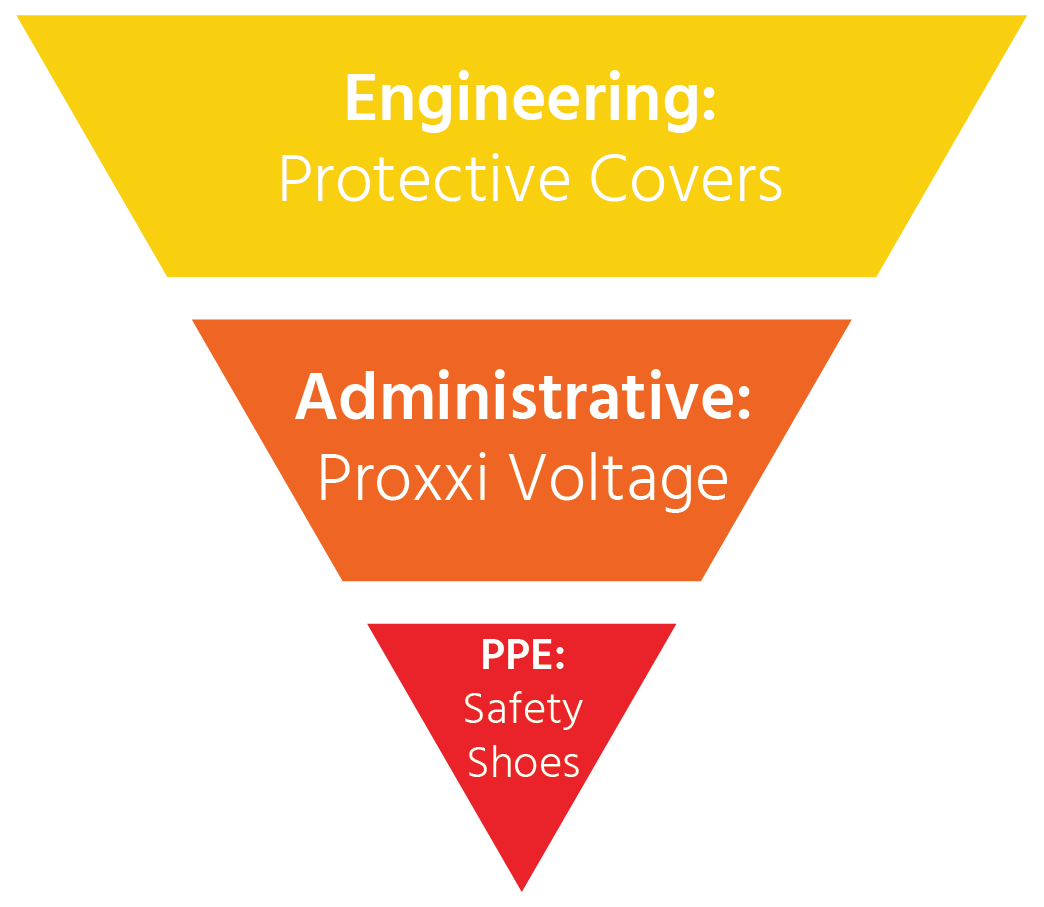

For companies where electricity is a potential risk, elimination and substitution are also often not feasible. Engineering controls such as protective covers for equipment to prevent a worker from contacting energized conductors or circuit parts. Many organizations also have existing administrative controls such as training and mandated processes. With Proxxi Voltage, additional administrative controls can be implemented by providing a warning to individuals of electrical risks, even when they do not expect to be at risk. Proxxi Voltage alerts individuals to danger before contact occurs.

Prioritizing safety is not only important from a legal standpoint, but also from an employee satisfaction and financial perspective. Safe work environments are strongly associated with job satisfaction and employee happiness.

Whichever items you include in your workplace safety plan, it is important to ensure that you are focusing first on implementing controls based on the top tiers of the hierarchy, and then working down. Lower tiers can come into play as backup to higher controls, and as options when the higher tiers are not feasible.